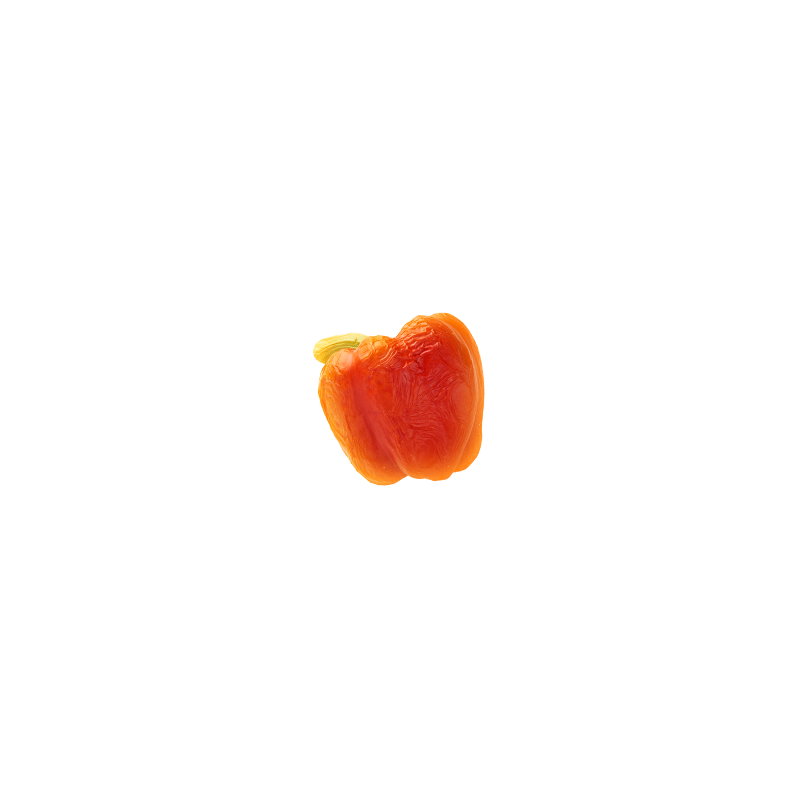

Step 1. Use quality ingredients

The ingredients produced at Asuzac Foods must meet food safety standards. Depending on the product, Asuzac Foods can use ingredients grown by Asuzac or raw materials Purchase from reputable suppliers. At the same time, customers provide raw materials and Asuzac will process and produce.

Step 2. Freeze in frozen storage

The raw materials, after going through the quality control process, will be preliminarily processed and frozen. In the cryogenic storage, the materials are controlled at a suitable freezing temperature, ensure not to affect or lose the natural flavor and nutritional content of the food.

Step 3. Dry by sublimation dryer

Raw materials after freezing will be transferred to the system of sublimation drying chambers. During the operation of the dryer, the water in the raw material that is in the solid state will slowly change directly to the vapor state without going through the liquid state (sublimation phenomenon).

Step 4. Quality check and packing

After drying, the raw materials will be checked for quality to ensure that they meet the specified quality criteria. Sensory inspection of color, taste, ability to restore the original state.

Asuzac only selects quality products that have been committed to customers after drying to deliver to customers. Currently, Asuzac Foods' freeze-dried and heat-dried foods are used as ingredients in instant products such as instant noodles, porridge, soups, confectionery, nutritional foods...

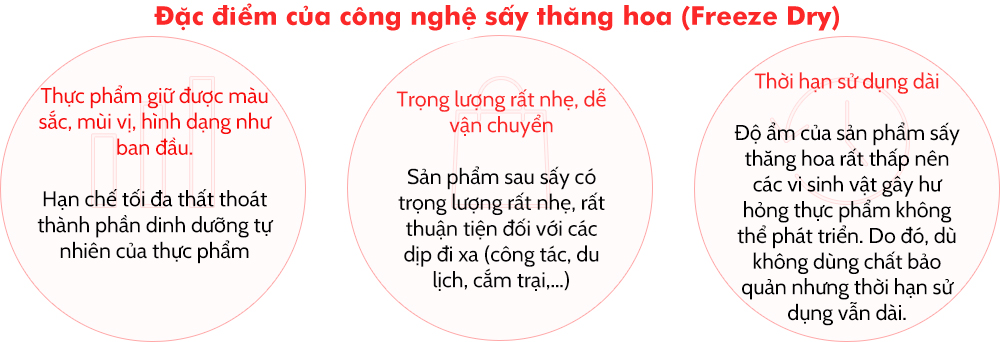

Sublimation drying products are lightweight, convenient to move

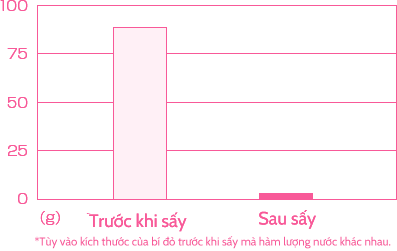

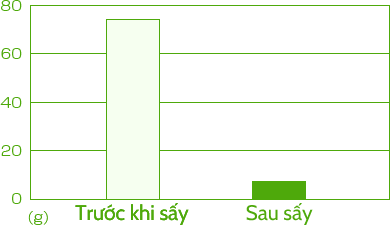

After sublimation drying, the amount of water in the product is only 1/10 of the original fresh state. Therefore, sublimated drying products are lightweight, convenient to move away.

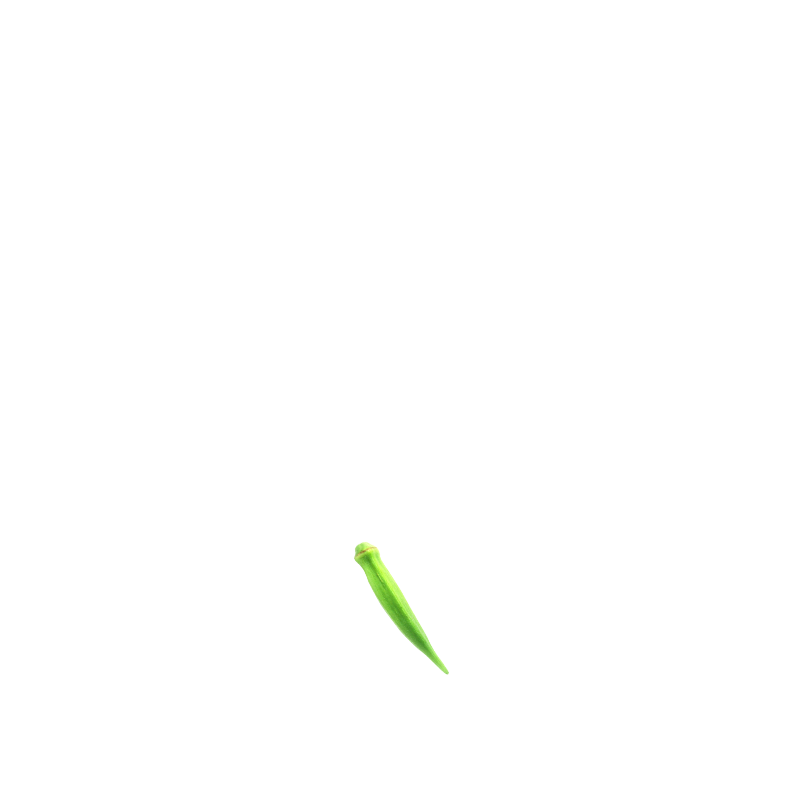

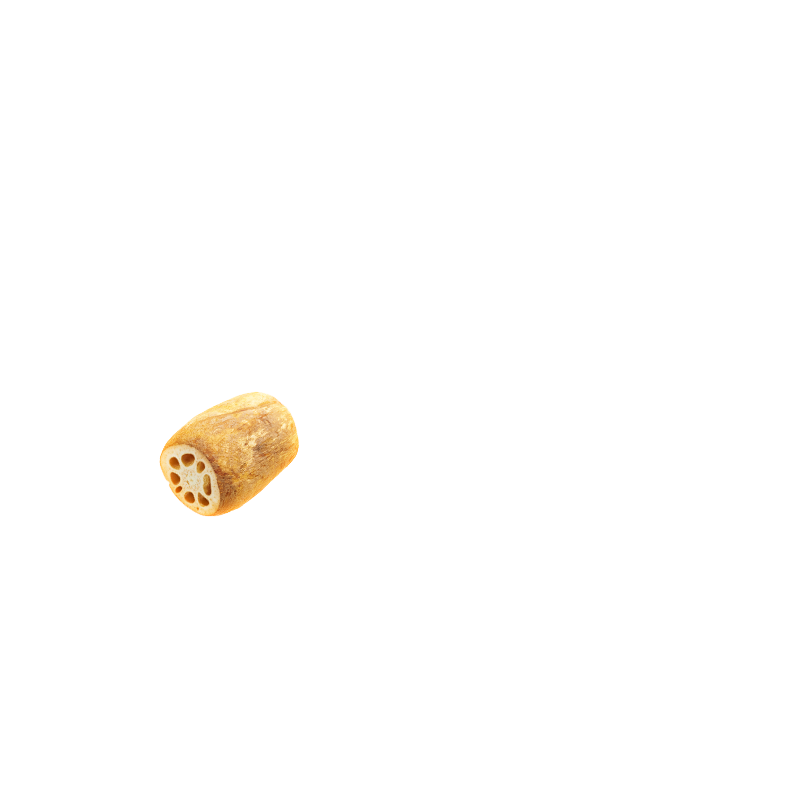

The photo on the right is a comparison of the weight of okra after drying and before drying.

Chart comparing the weight of sublimated dried okra and fresh okra

Sublimation drying can be stored for a long time

After sublimation drying, the amount of water in the product is extremely low, therefore microorganisms are not qualified to grow. Therefore, post-drying products can be stored for a long time without the use of any preservatives.

The chart compares the amount of water of pumpkins before and after sublimation drying.